FEATURES

WACCINE Compo's 'Flying' Design and Technology

KEY HIGHLIGHTS

Lightweight & Stability

Offers a comfortable swing feel

Flexibility & Resilience

Provides a quick shaft recovery

QUAD

PERFORMANCE

DESIGN

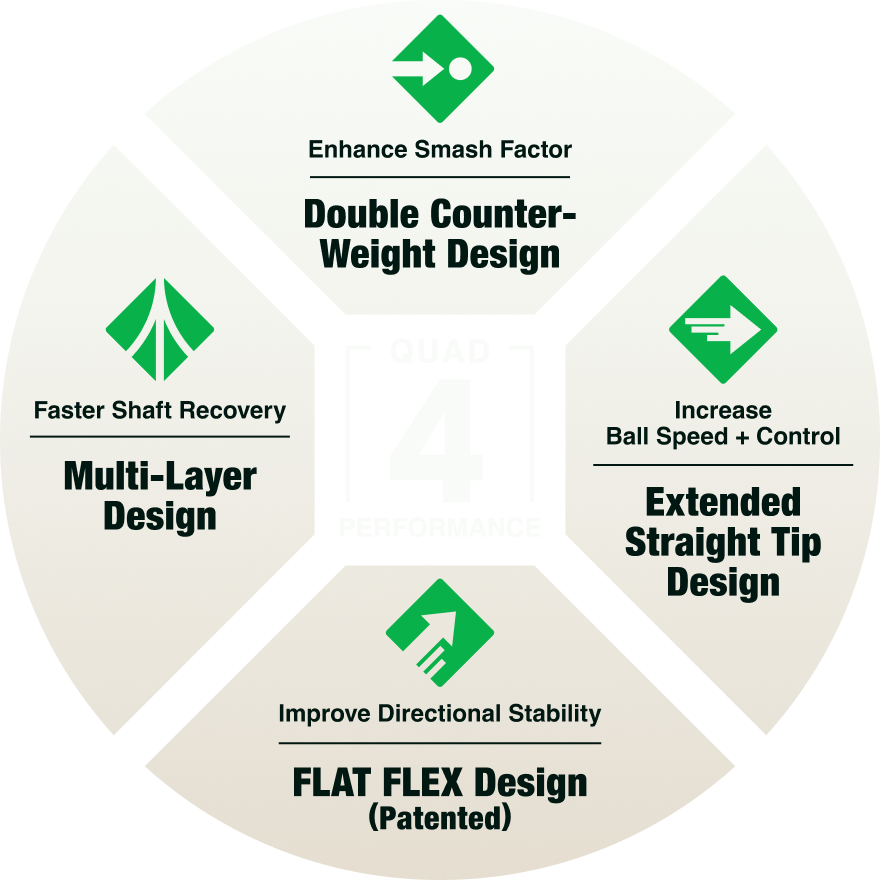

Achieve “Your Distance of -10 Years ago” with 4 Advanced High-Performance Features

Engineered to maximize both distance and score

improvement,

our shaft brand introduces

an industry-first* proprietary

design focused on

delivering

unparalleled performance.

*The revolutionary 'FLAT FLEX Design' offers consistent flex across all clubs from driver to sand wedge,

breaking conventional industry norms, making it the first of its kind.

Enhance Smash Factor

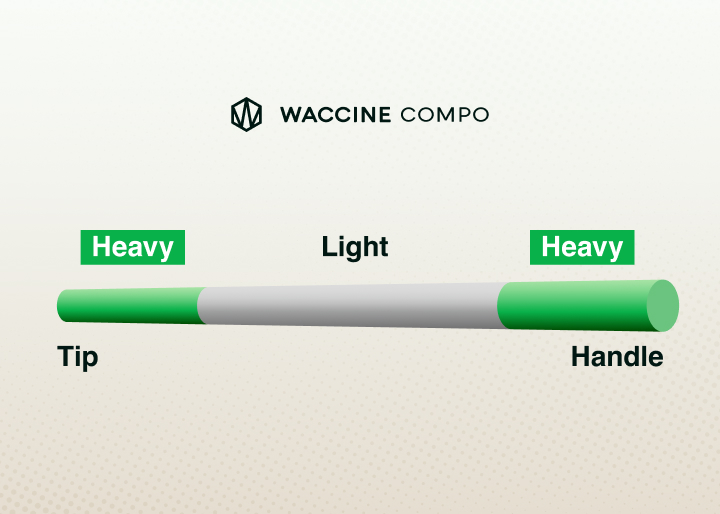

Double Counterweight Design

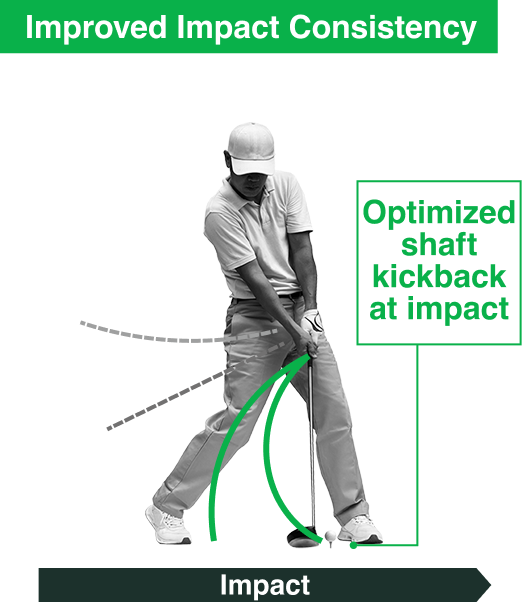

This innovative technology maintains the overall shaft weight while strategically distributing mass to both the grip and tip sections. It allows golfers to effectively manipulate the club's moment of inertia, balancing the sensations of "heaviness" and "lightness" throughout the swing, which enhances the swing efficiency. During the downswing, the club feels heavier, promoting increased stability and improving impact consistency. During the follow-through, the club feels lighter, facilitating a smoother release and enabling higher head speeds.

Faster Shaft Recovery

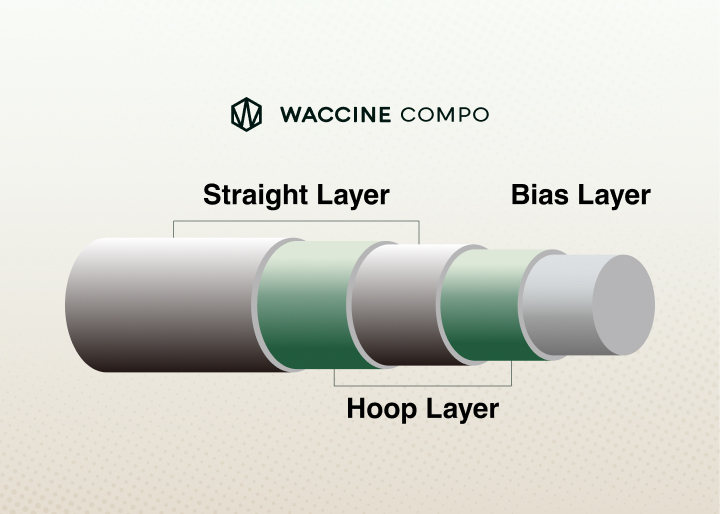

Multi-Layer Design

The 'Multi-Layer Design' incorporates a combination of high, medium, and low-elasticity materials in the straight, hoop, and bias layers of the shaft. This innovative approach allows for the creation of ultra-low and ultra-high torque shafts, facilitating rapid shaft recovery and significantly improving initial ball speed. By combining high-elasticity materials with boron—a lightweight, high-strength fiber traditionally used in aerospace—this advanced shaft design enhances the shaft's strength and resilience, allowing for efficient energy transfer during the swing, resulting in improved ball acceleration and greater distance.

Increase Ball Speed + Control

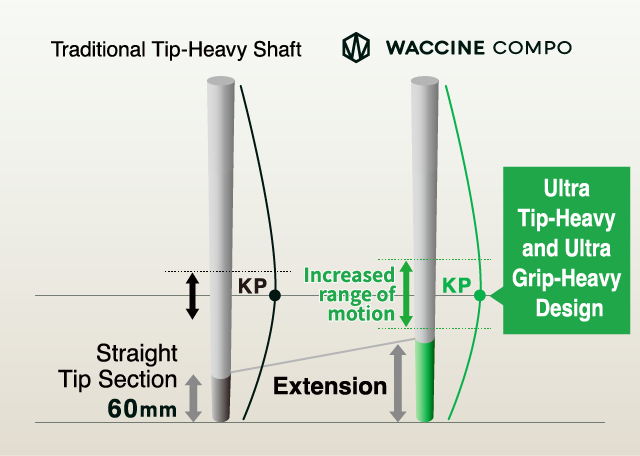

Extended Straight Tip Design

By extending the straight section at the tip of the shaft up to three times longer than conventional designs, this innovation significantly expands the range of the kick point—the area where the shaft bends most during the swing. This advancement enables the creation of shafts with ultra-tip-flex or ultra-butt-flex profiles, resulting in faster shaft recovery and improved ball control.

Note: The "kick point" refers to the section of the shaft that bends most during the swing, influencing the trajectory and feel of the shot.

Improve Directional Stability

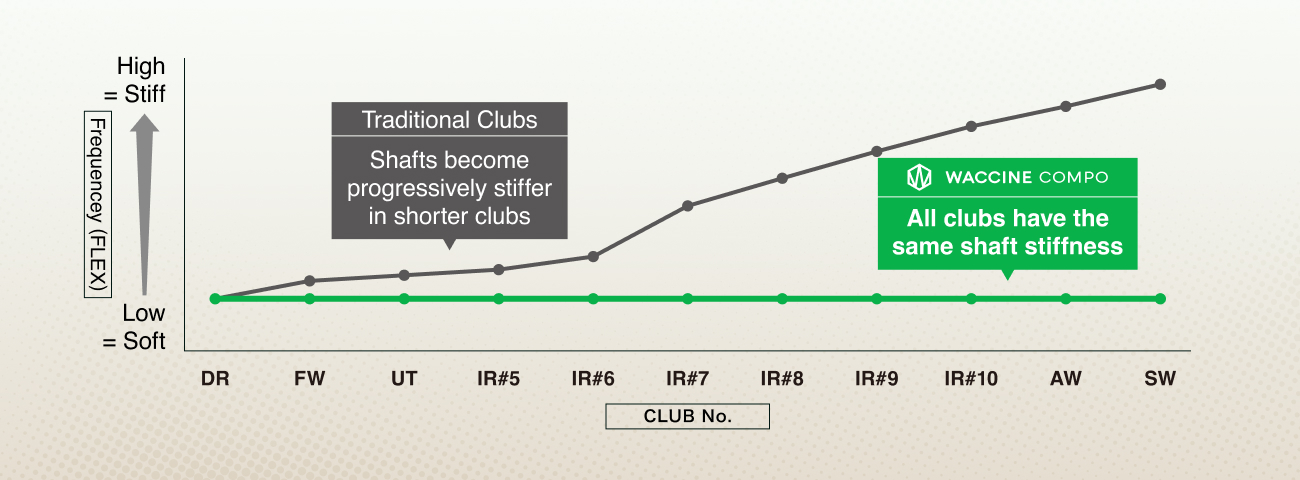

Industry-First: FLAT FLEX Design*

(Patented)

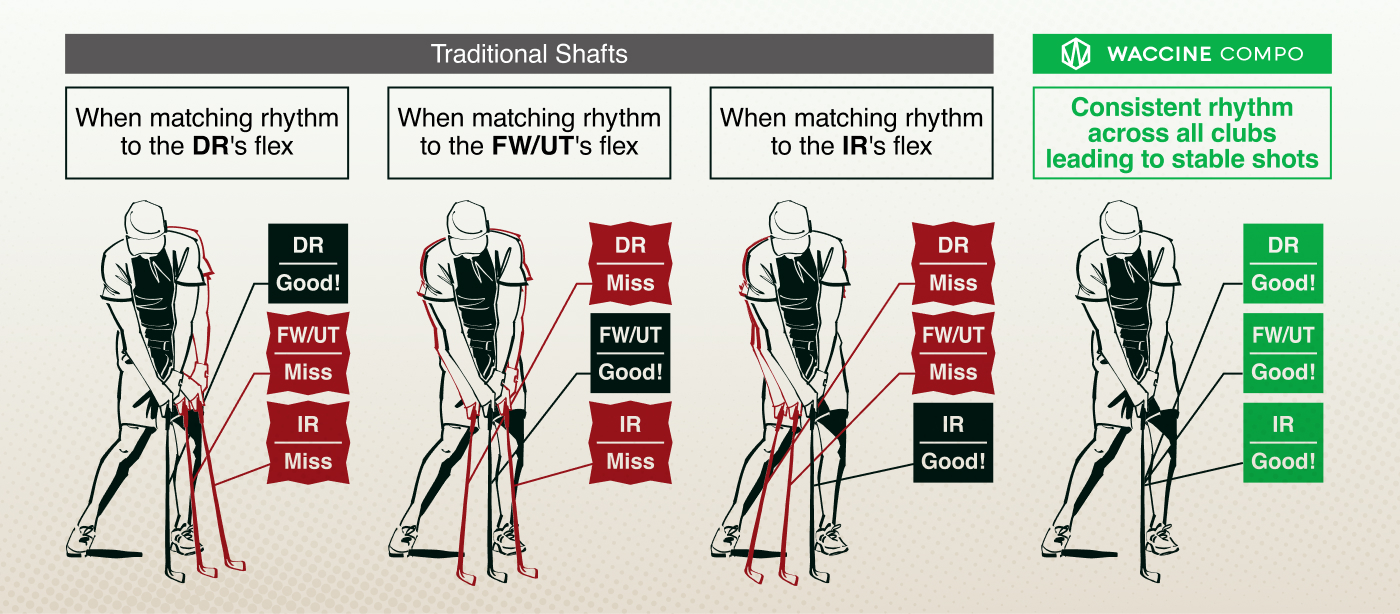

By intentionally standardizing shaft flex (frequency) across all club types, this design achieves consistent swing feel and improved shot stability. This innovative approach challenges traditional industry norms, embodying WACCINE Compo's unique golf philosophy.

*Patent Acquisitio JP 7099857

Traditional golf clubs often feature varying shaft flex (frequency) across different club numbers, leading to inconsistencies in swing feel and shot stability.

To solve this issue, the FLAT FLEX Design standardizes shaft flex across all clubs, from driver to sand wedge. This uniformity eliminates the need for golfers to subconsciously adjust their swing rhythm for each club, resulting in improved shot consistency and overall performance. By providing a consistent flex profile throughout the set, golfers can experience a more predictable and stable swing, enhancing confidence and accuracy on the course.

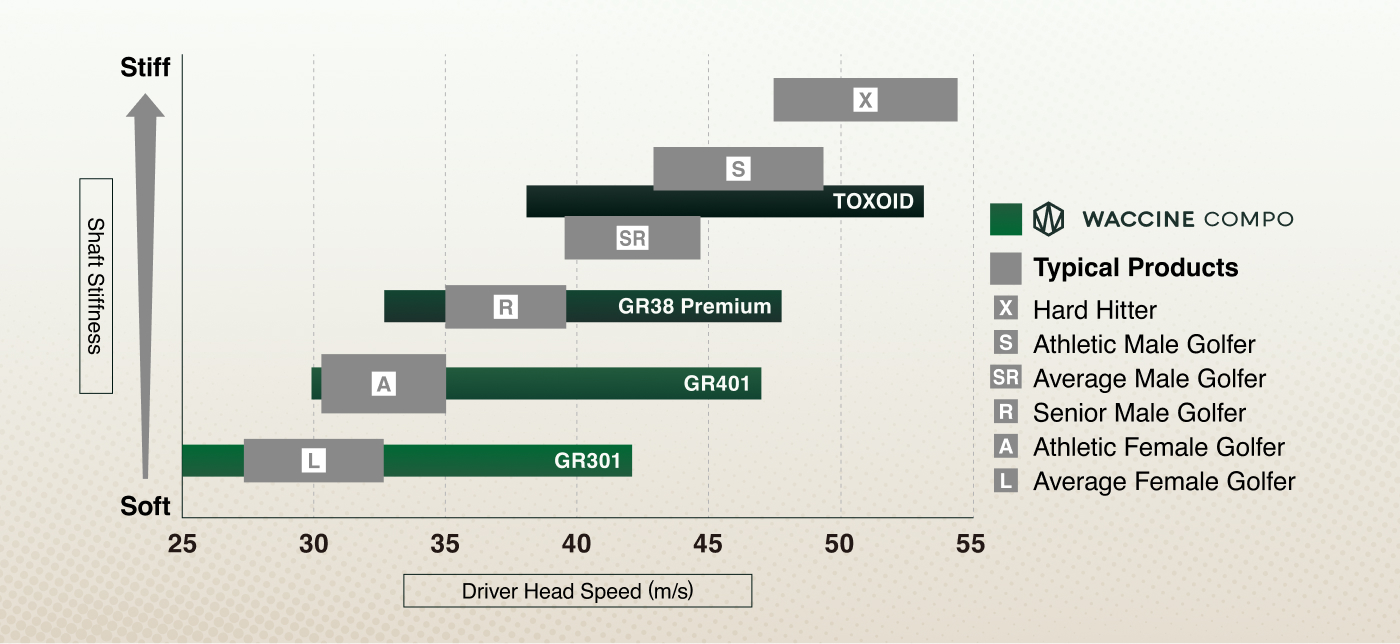

WACCINE COMPO offers a diverse range of shafts designed to deliver the exhilarating sensation of distance to golfers of all levels. From soft to hard hitters, we provide shafts suited to various head speeds, ranging from 25 to 53 m/s.

TECHNICALTechnology and Material

Dedicating years of research to develop the optimal materials and manufacturing processes, we create golf shafts that deliver exceptional performance. Our commitment to uncompromising craftsmanship ensures that golfers of all levels can experience the thrill of increased distance and precision with every shot.

Custom Core Metal Inserts

for Each Club

The remarkable performance of WACCINE shafts stems from our proprietary development of the shaft's core component, the mandrel, which is the heart of the shaft. By meticulously adjusting the weight distribution in specific sections, our developers design precise configurations tailored to each club type. This intricate process requires over a year to complete, ensuring that every shaft delivers unparalleled stability and distance.

Each mandrel is uniquely crafted for different clubs—from drivers to irons—allowing us to optimize performance across all applications. This dedication to specialized design is what enables WACCINE shafts to achieve their signature long-distance capabilities.

Craftsmanship in

Carbon Shaft Manufacturing

Each carbon shaft is crafted by carefully cutting sheets of carbon fiber and tungsten into precise shapes. These materials are then hand-wrapped around a specially designed mandrel, forming the core structure of the shaft. Once assembled, the shaft undergoes a controlled heating process in an electric kiln, ensuring the materials bond securely and achieve optimal strength. After curing, skilled artisans manually polish the shaft to achieve uniform thickness and a flawless finish. This blend of traditional craftsmanship and advanced technology results in golf shafts that offer unparalleled consistency, responsiveness, and performance on the course.

Commitment to

100% Japanese Materials

We are dedicated to using only premium, 100% domestically sourced materials. Through stringent temperature control during manufacturing, we consistently maintain the purity of these materials.

Our shafts incorporate a variety of materials—including carbon fiber, boron, titanium, ceramic, aluminum, and steel—each selected to optimize specific shaft characteristics. This meticulous material selection ensures that every shaft delivers exceptional performance tailored to the needs of golfers.

HISTORYOur Development Journey

WACCINE COMPO was born from a desire to address the challenges observed in golf shafts over years of experience in the industry. Traditionally, lighter shafts are easier to swing but can lead to decreased accuracy, while heavier shafts improve accuracy but may reduce head speed.

Similarly, softer shafts can generate more distance when struck perfectly but often compromise directional stability, whereas stiffer shafts offer control but may limit distance.

These inherent trade-offs have long posed a dilemma for golfers, prompting us to question whether a shaft could be engineered to deliver both ease of swing and consistent performance.

This fundamental inquiry has been at the heart of our innovation.

In 2008, significant changes were introduced to golf equipment regulations, notably limiting the coefficient of restitution of driver faces and capping clubhead. Recognizing that these restrictions would curtail advancements in clubhead design, we anticipated that the spotlight would soon shift to shaft innovation.

Motivated by this foresight, we established Gravity Co., Ltd. in 2009 and launched the WACCINE COMPO brand. Through extensive research and experimentation, we discovered that altering the weight distribution within the shaft could significantly influence swing dynamics.

This led to the development of our proprietary 'Double Counterweight Design' which makes lighter shafts feel heavier and heavier shafts feel lighter, enhancing both control and swing speed.

This groundbreaking approach culminated in the release of our inaugural product, the

WACCINE COMPO GR50, setting a new standard in shaft performance and offering golfers an

unparalleled combination of power and precision.

As our brand continued to grow, we revisited a longstanding convention in golf shaft design: the progressive increase in shaft stiffness from driver to wedge. Traditionally, shafts are engineered to become progressively stiffer as the club length decreases, with wedges being the stiffest.

This design approach assumes that shorter clubs require more control, hence the increased stiffness. However, we questioned whether this progression truly benefits all golfers. Does a stiffer wedge shaft necessarily lead to better performance, or could a uniform flex across all clubs provide more consistent swing dynamics?

Our exploration into this question led us to develop innovative shaft designs that challenge traditional norms, aiming to enhance consistency and performance throughout the entire set.

After five years of dedicated research and development, WACCINE COMPO successfully developed a groundbreaking shaft that delivers consistent flex and stiffness from driver to wedge. This achievement was made possible by focusing on the mandrel—the core component of the shaft—and crafting it into a unique shape, departing from traditional shaft manufacturing methods.

This innovative approach led to the creation of our proprietary 'FLAT FLEX Design', which ensures uniform flex characteristics across all club types. As a result, golfers experience consistent swing timing and feel throughout their entire set, enhancing shot stability and overall performance.

The FLAT FLEX Design has garnered high praise from golfers seeking improved distance and control, solidifying WACCINE COMPO's reputation as a leader in shaft innovation.