WACCINE compo. TOXOID

50/60/70/80/90 Series

Exclusive Global Model For The World

The Best Ball Contact Of WACCINE's History

Increase average flight distance by +12 yards in 18H

(According to in-house research when used with our 50 S shaft)

WACCINE COMPO'S

TRIPLE THREAT

Revolutionizing shaft with competitive advantage.

With the ultimate priority of driving distance, 'WACCINE compo. TOXOID is an unrivelled shaft made of propriety design using the highest quality standards that cannot be imitated anywhere else.

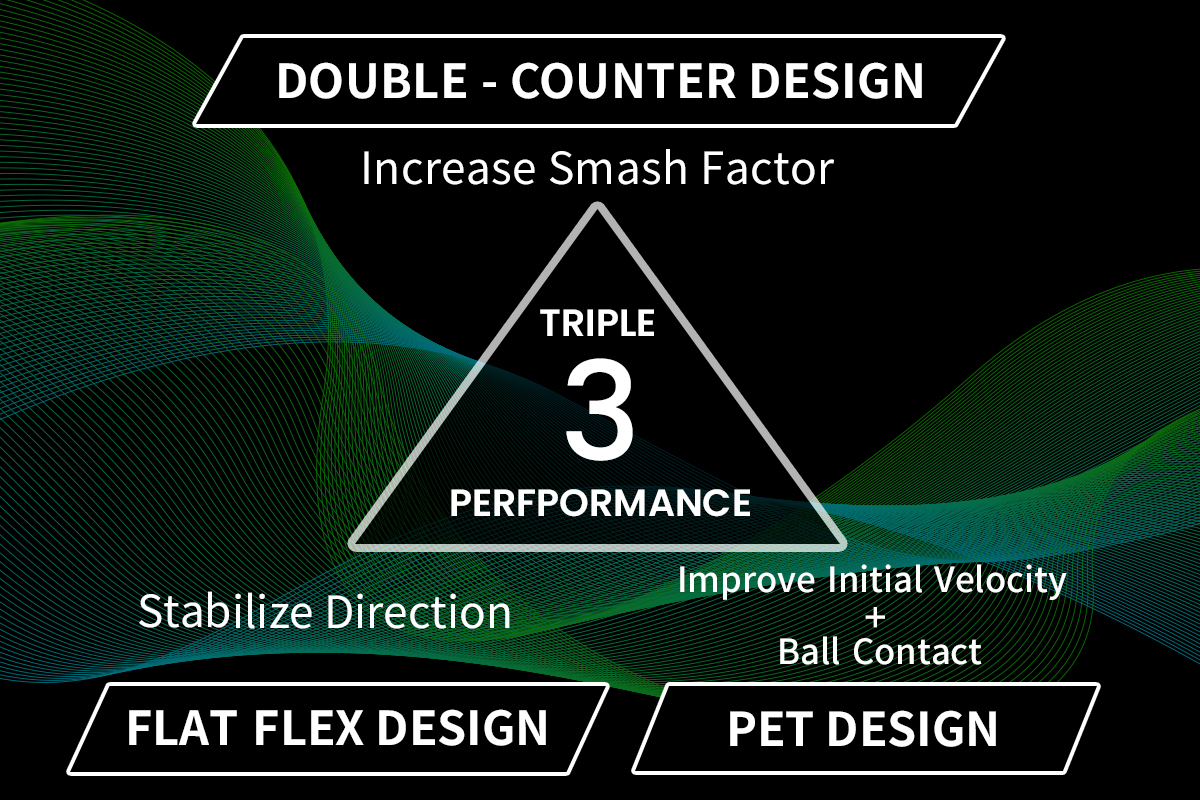

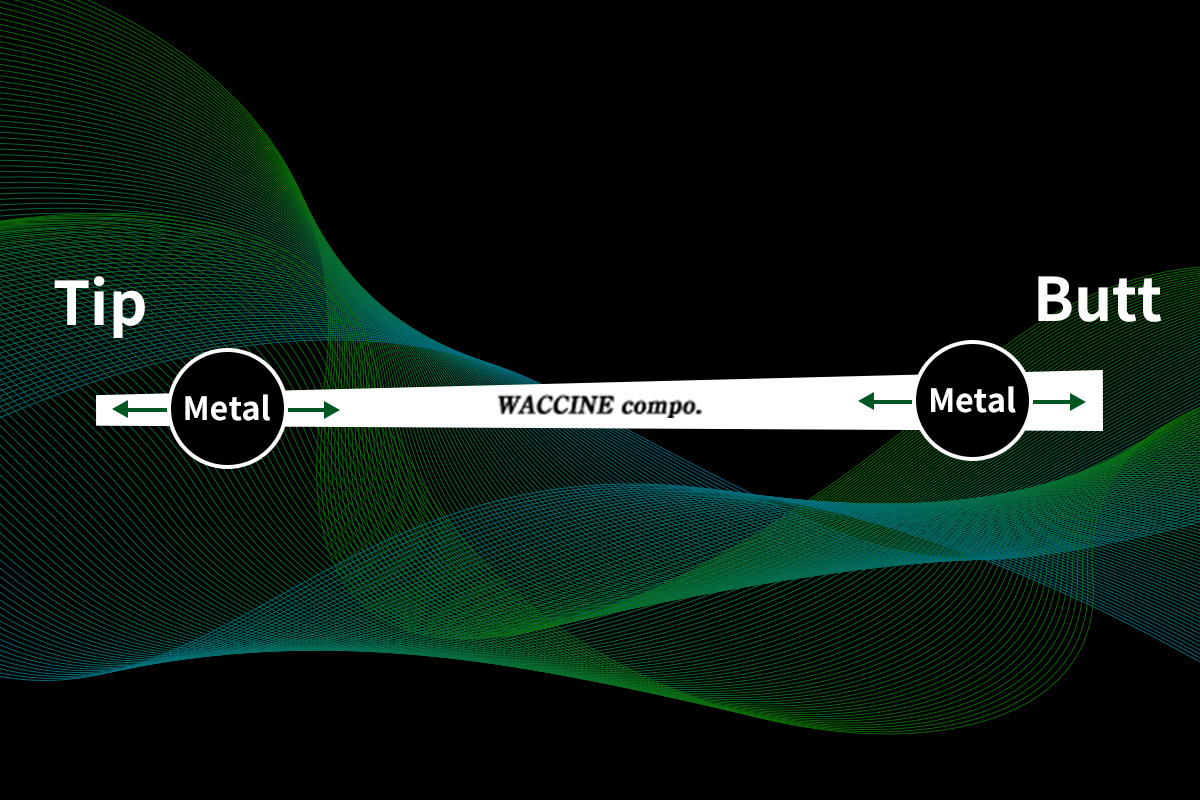

DOUBLE-COUNTER DESIGN (Pendulum Weight Distribution Design) since 2009

Manipulate "heavy" and "light" freely to increase your smash factor.

Unique formulation of metal at the tip and butt of the shaft. Maximize your swing and smash factor by the ability to feel the weight despite its lightness, and vice-a-versa, improve your swing-through and increase clubhead speed by the ability to feel lightness despite its weight. This proprietary mechanism allows optimal weight distribution that is suited for every type of golfer.

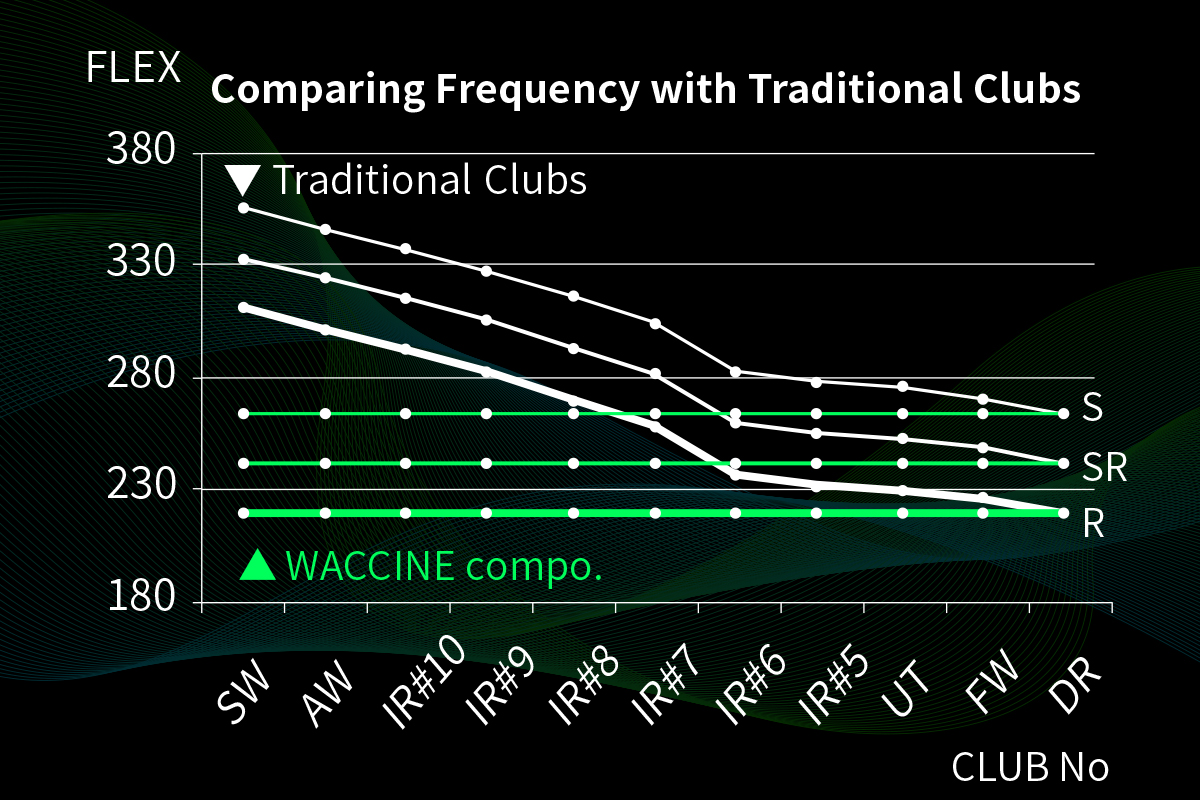

FLAT FLEX DESIGN (EVEN FREQUENCY MECHANISM Patent Pending) since 2018

Enables consistent swing from drivers to irons and stabilize direction.

In conventional golf clubs, the frequency of the shaft changes with each club which causes inconsistency in shots. As a solution, we have integrated 'FLAT FLEX DESIGN' which stabilizes the frequency of the shafts from drivers to sandwedge. With this innovative approach, you can expect an evolution in your driving distance and achieve a better score.

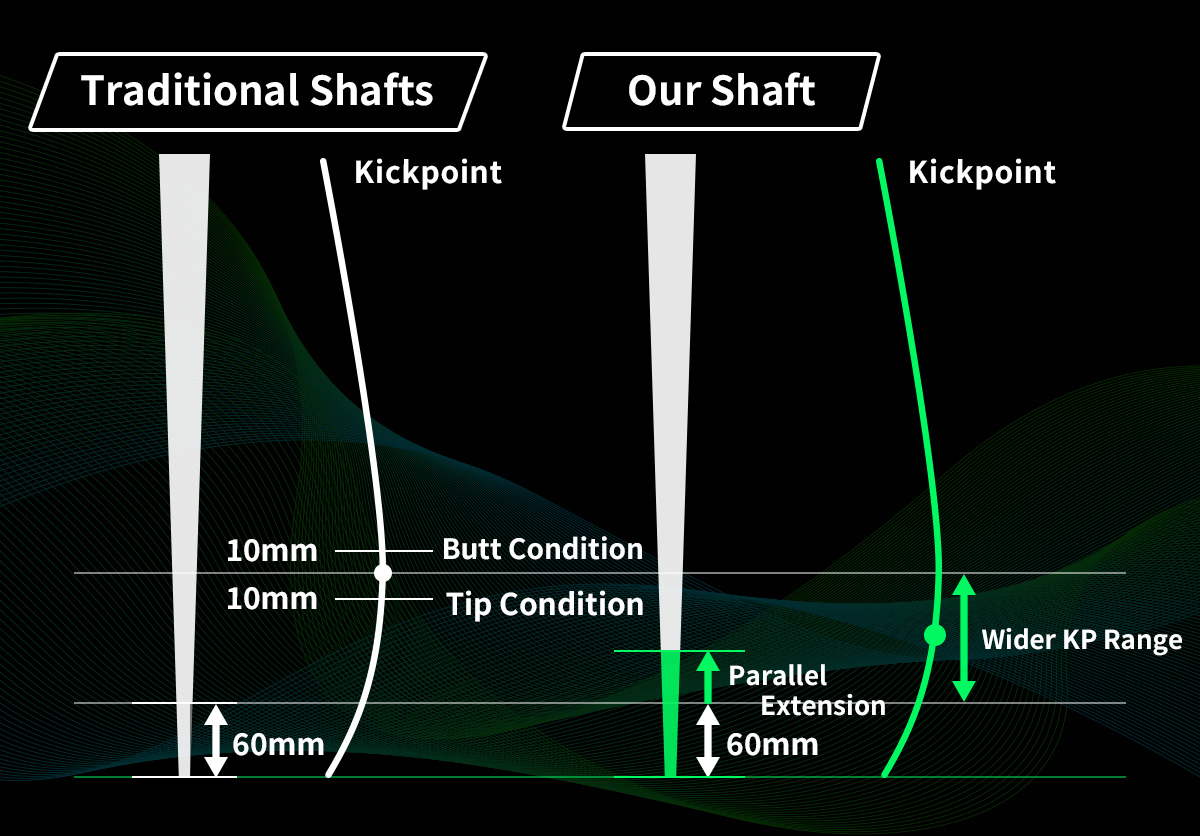

PET DESIGN (ULTRA-THIN PARALLEL TIP MECHANISM Patent Pending) since 2020

Improve 'initial velocity' and 'ball contact'.

With the conventional shape of a shaft, the allowable range of kick point (KP) was ± 10 mm, but by extending the straight tip length (parallel part) to about twice that of the existing shaft, the range of motion of KP has expanded dramatically. With our manufacturing technology, we are able to produce super-low KP shafts that have achieved unprecedented performance.

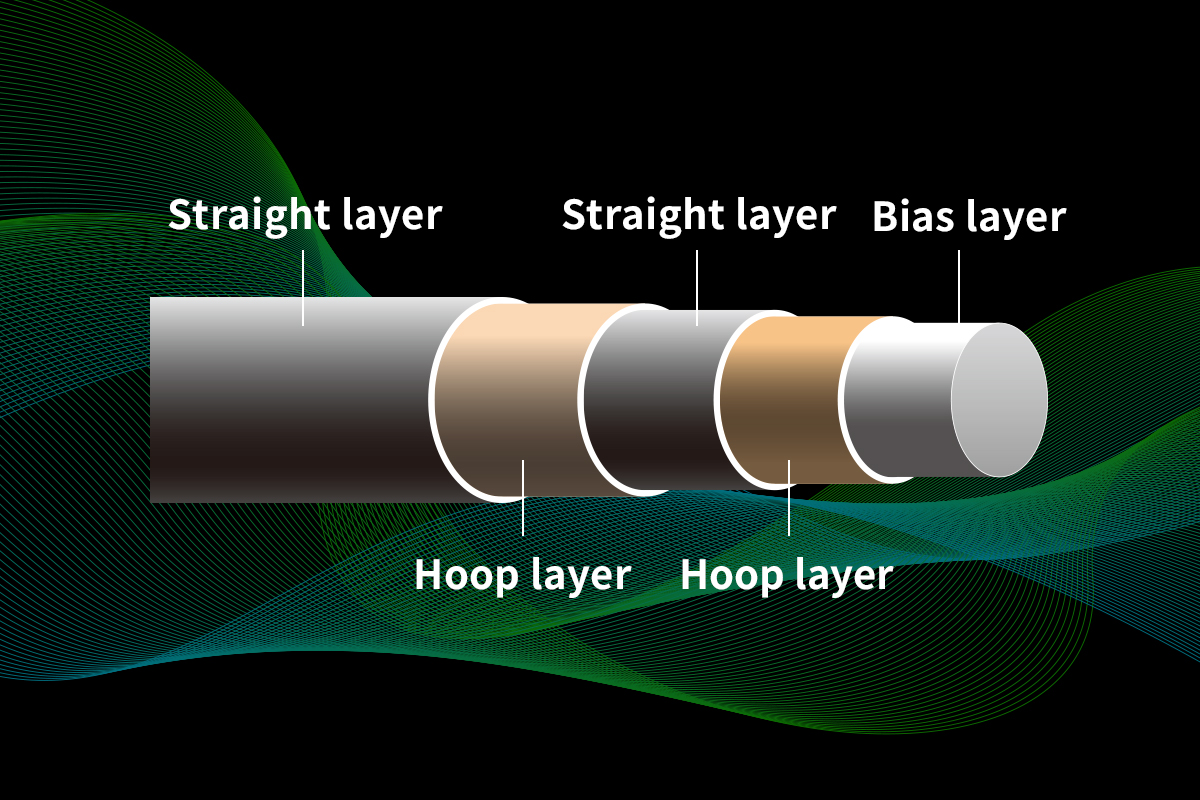

Carefully selected materials for those who wish to increase their distance

Highly elastic carbon and boron are incorporated in the optimal areas.

The initial speed is improved by quick bend-back.

Improved catch with high torque design. Sophisticated layer design (straight, hoop, bias layer) with high, medium and low elasticity materials are optimally combined to improve the overall ball catch.

Uses high-strength carbon fiber "T-1100G".

Combining this carbon fiber with the strength of the waist that pushes out the ball, it results in high strength low spin while still being lightweight.

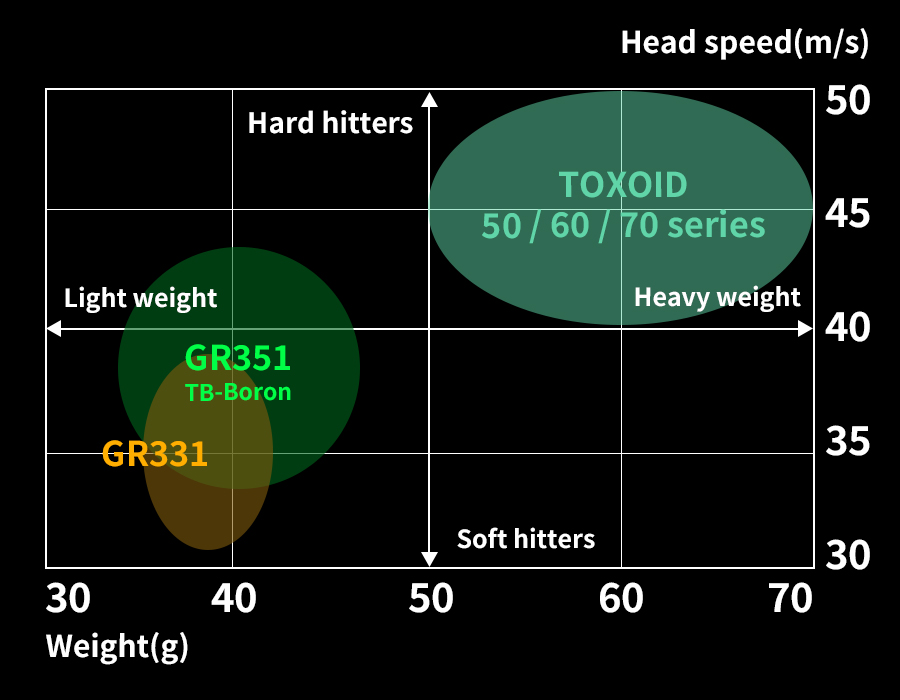

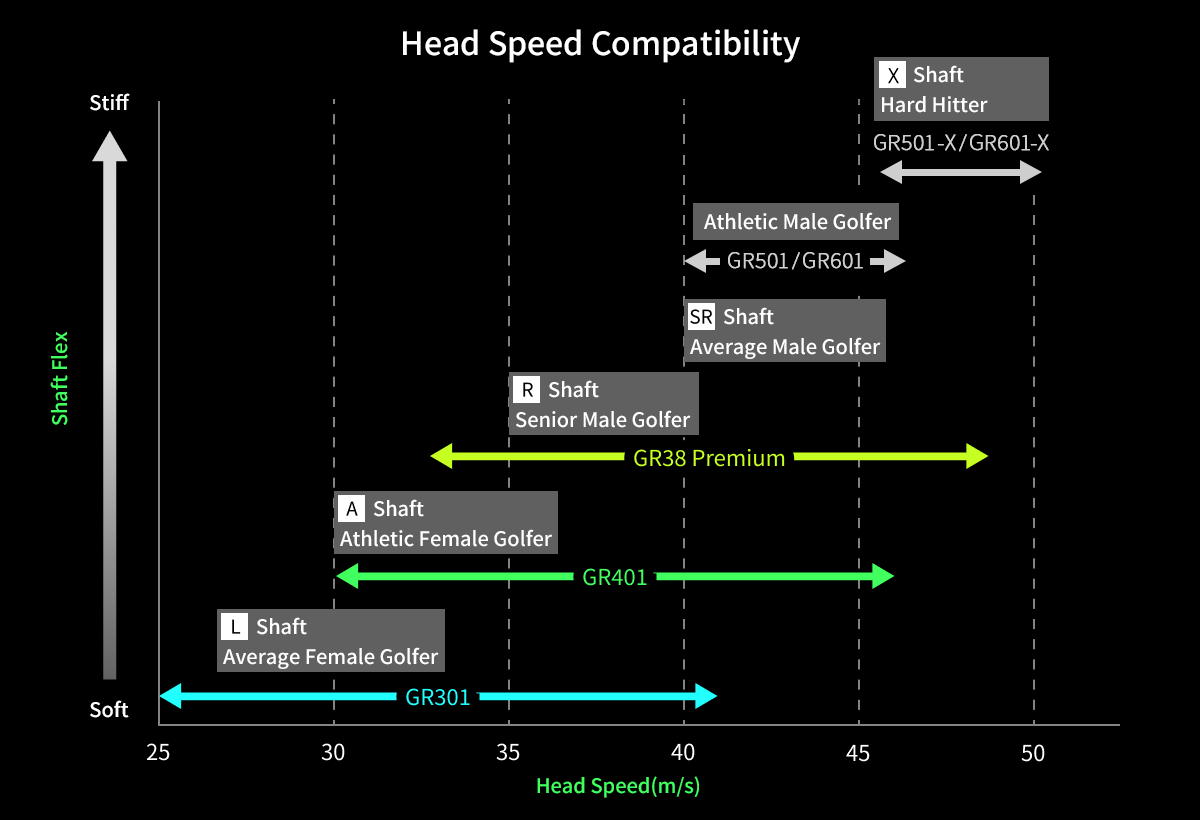

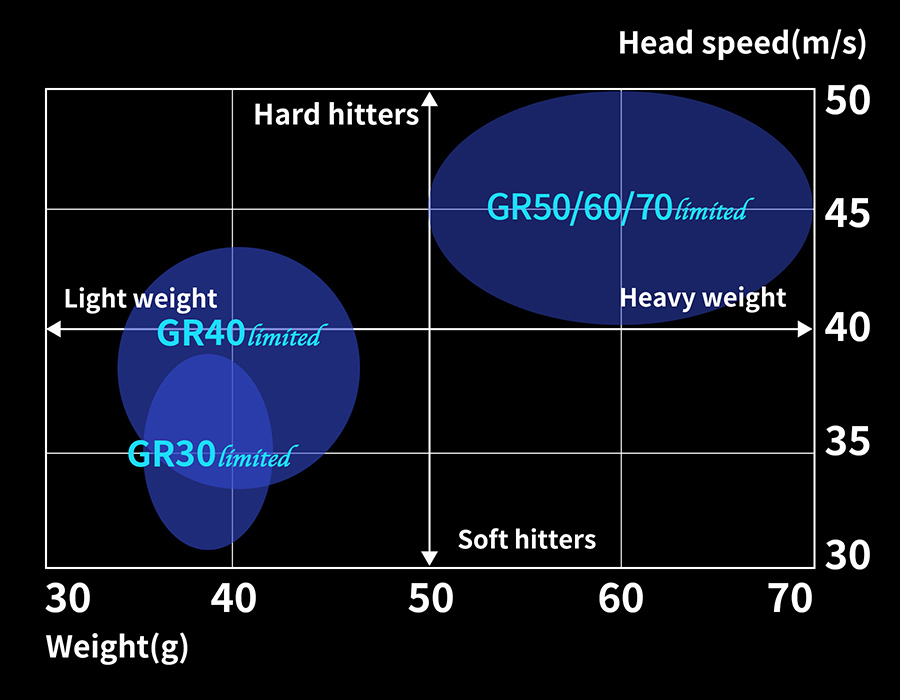

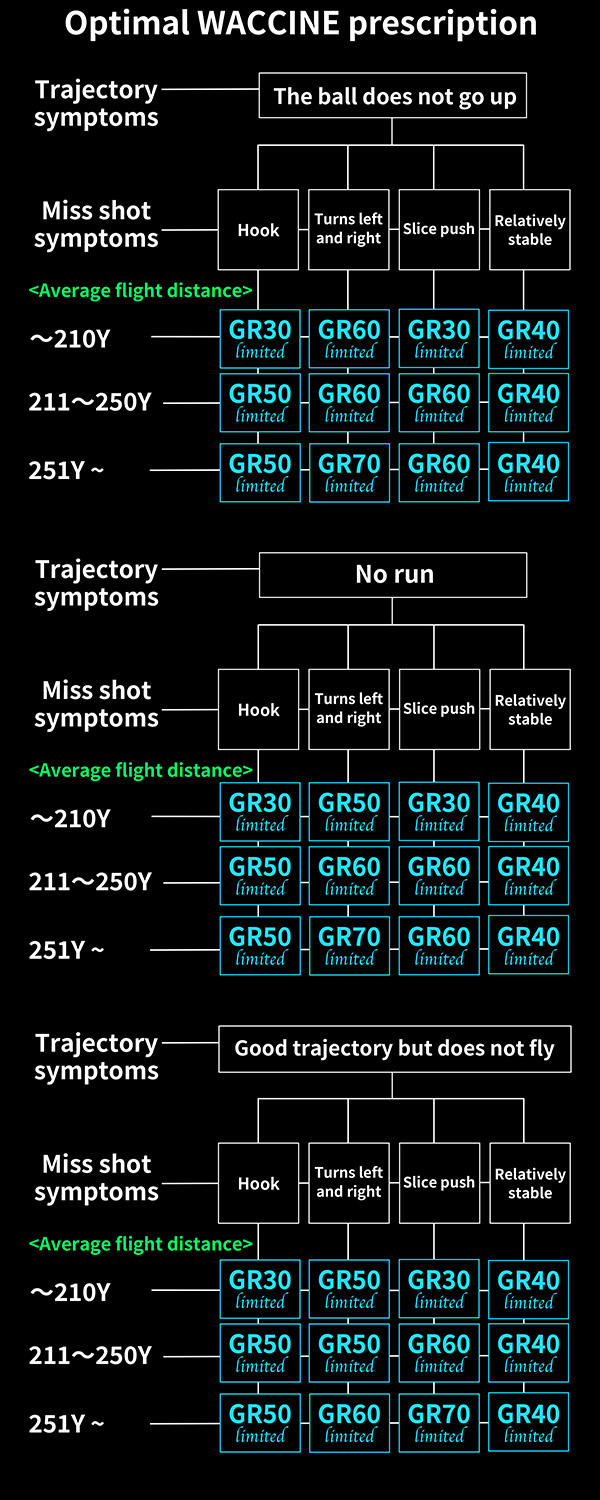

Target golfers who:

- HS38-50m/s

- Hit balls that go to the left and right (direction instability)

- Cannot achieve any run

Shaft suitability by Golfer Type

Bending distribution map

Product specifications

discretionary price

| Flex | R | SR | S | X |

|---|---|---|---|---|

| Fit in H/S | 32-36 | 37-41 | 42-46 | 47-51 |

| Weight(g) | 49 | 50 | 52 | 54 |

| Kick point | Medium | Medium High | Medium High | High |

| Torque | 6 | 5.5 | 5 | 4.5 |

| New Frequency (cpm) |

220 | 235 | 250 | 265 |

| Length (Mm) |

1181 | 1181 | 1181 | 1181 |

| Thickness | 15.1 | 15.2 | 15.3 | 15.4 |

*The frequency is a reference value when setting DR-45.5 D2 to the 60 degree measurement method.

discretionary price

| Flex | R | SR | S | X |

|---|---|---|---|---|

| Fit in H/S | 32-36 | 37-41 | 42-46 | 47-51 |

| Weight(g) | 50 | 52 | 53 | 55 |

| Kick point | Medium | Medium High | Medium High | High |

| Torque | 6 | 5.5 | 5 | 4.5 |

| New Frequency (cpm) |

215 | 230 | 245 | 260 |

| Length (Mm) |

1118 | 1118 | 1118 | 1118 |

| Thickness | 15.1 | 15.2 | 15.3 | 15.4 |

*The frequency is a reference value when the tip insertion length is 30mm and the 60 degree measurement method is set to the DR-45.5 D2.

discretionary price

| Flex | SR | S | X |

|---|---|---|---|

| Fit in H/S | 40-43 | 44-47 | 48-51 |

| Weight(g) | 58 | 60 | 63 |

| Kick point | Medium High | High | High |

| Torque | 5.5 | 5 | 4.5 |

| New Frequency (cpm) |

230 | 245 | 260 |

| Length (Mm) |

1181 | 1181 | 1181 |

| Thickness | 15.3 | 15.4 | 15.5 |

*The frequency is a reference value when setting DR-45.5 D2 to the 60 degree measurement method.

discretionary price

| Flex | SR | S | X |

|---|---|---|---|

| Fit in H/S | 40-43 | 44-47 | 48-51 |

| Weight(g) | 61 | 63 | 64 |

| Kick point | Medium High | High | High |

| Torque | 5 | 4.5 | 4 |

| New Frequency (cpm) |

225 | 240 | 255 |

| Length (Mm) |

1118 | 1118 | 1118 |

| Thickness | 15.3 | 15.4 | 15.5 |

*The frequency is a reference value when the tip insertion length is 30mm and the 60 degree measurement method is set to the DR-45.5 D2.

discretionary price

| Flex | R | SR | S |

|---|---|---|---|

| Fit in H/S | 36-39 | 40-43 | 42-46 |

| Weight(g) | 60 | 62 | 64 |

| Kick point | High | Medium High | Medium High |

| Torque | 6 | 5.5 | 5 |

| New Frequency (cpm) |

220 | 235 | 250 |

| Length (Mm) |

1041 | 1041 | 1041 |

| Thickness | 15.1 | 15.2 | 15.3 |

*The frequency is a reference value when the tip insertion length is 30mm and the 60 degree measurement method is set to the DR-45.5 D2.

discretionary price

| Flex | R | SR |

|---|---|---|

| Fit in H/S | 32-36 | 37-41 |

| Weight(g) | 61 | 63 |

| Kick point | High | Medium High |

| Torque | 5 | 4.5 |

| New Frequency (cpm) |

230 | 245 |

| Length (Mm) |

991 | 991 |

| Thickness | 15.2 | 15.3 |

*The frequency is a reference value when the tip insertion length is 30mm and the 60 degree measurement method is set to the #7-37inches D1.

discretionary price

| Flex | S | X |

|---|---|---|

| Fit in H/S | 44-47 | 48-51 |

| Weight(g) | 68 | 70 |

| Kick point | High | High |

| Torque | 4 | 3.5 |

| New Frequency (cpm) |

250 | 270 |

| Length (Mm) |

1181 | 1181 |

| Thickness | 15.4 | 15.5 |

*The frequency is a reference value when setting DR-45.5 D2 to the 60 degree measurement method.

discretionary price

| Flex | S | X |

|---|---|---|

| Fit in H/S | 44-47 | 48-51 |

| Weight(g) | 71 | 73 |

| Kick point | High | High |

| Torque | 4 | 3.5 |

| New Frequency (cpm) |

245 | 265 |

| Length (Mm) |

1118 | 1118 |

| Thickness | 15.5 | 15.6 |

*The frequency is a reference value when the tip insertion length is 30mm and the 60 degree measurement method is set to the DR-45.5 D2.

discretionary price

| Flex | S | X |

|---|---|---|

| Fit in H/S | 44-47 | 48-51 |

| Weight(g) | 74 | 76 |

| Kick point | High | High |

| Torque | 3.5 | 3 |

| New Frequency (cpm) |

245 | 260 |

| Length (Mm) |

1041 | 1041 |

| Thickness | 15.4 | 15.5 |

*The frequency is a reference value when the tip insertion length is 30mm and the 60 degree measurement method is set to the DR-45.5 D2.

discretionary price

| Flex | SR |

|---|---|

| Fit in H/S | 40-43 |

| Weight(g) | 72 |

| Kick point | Medium High |

| Torque | 4 |

| New Frequency (cpm) |

250 |

| Length (Mm) |

991 |

| Thickness | 15.4 |

*The frequency is a reference value when the tip insertion length is 30mm and the 60 degree measurement method is set to the #7-37inches D1.

discretionary price

| Flex | S | X |

|---|---|---|

| Fit in H/S | 44-47 | 48-51 |

| Weight(g) | 85 | 86 |

| Kick point | High | High |

| Torque | 3 | 2.5 |

| New Frequency (cpm) |

250 | 270 |

| Length (Mm) |

1041 | 1041 |

| Thickness | 15.6 | 15.8 |

*The frequency is a reference value when the tip insertion length is 30mm and the 60 degree measurement method is set to the DR-45.5 D2.

discretionary price

| Flex | S |

|---|---|

| Fit in H/S | 44-47 |

| Weight(g) | 85 |

| Kick point | High |

| Torque | 3.5 |

| New Frequency (cpm) |

260 |

| Length (Mm) |

991 |

| Thickness | 15.7 |

*The frequency is a reference value when the tip insertion length is 30mm and the 60 degree measurement method is set to the #7-37inches D1.

discretionary price

| Flex | S | X |

|---|---|---|

| Fit in H/S | 44-47 | 48-51 |

| Weight(g) | 95 | 97 |

| Kick point | High | High |

| Torque | 3 | 2.5 |

| New Frequency (cpm) |

270 | 285 |

| Length (Mm) |

991 | 991 |

| Thickness | 15.8 | 16 |

*The frequency is a reference value when the tip insertion length is 30mm and the 60 degree measurement method is set to the #7-37inches D1.

FW

| Length | Tip cut |

|---|---|

| 42 or over | 0 |

| 42-41.5 | 1/4 |

| 41.5-41 | 1/2 |

| 41-40.5 | 3/4 |

| Under 40 | 1 |

UT

| Length | Tip cut |

|---|---|

| 40 or over | 0 |

| 40-39.5 | 1/4 |

| 39.5-38.5 | 1/2 |

| 38.5-38 | 3/4 |

| Under 38 | 1 |

IR

| Length | Tip cut |

|---|---|

| 38.5 or over | 0 |

| 38-38.5 | 0.5 |

| 37.5-38 | 1 |

| 37-37.5 | 1.5 |

| 36.5-37 | 2 |

| 36-36.5 | 2.5 |

| Under 36 | 3 |